Skräddarsydda olika storlekar av plastfanérplywood

Produktbeskrivning

Denna produkt används främst i kommersiella höghus, gjuttak, balkar, väggar, pelare, trappor och fundament, broar och tunnlar, vattenskydds- och vattenkraftprojekt, gruvor, dammar och underjordiska projekt.

Plastbelagd plywood har blivit byggbranschens nya favorit för dess miljöskydd och energibesparing, återvinningsekonomi och ekonomiska fördelar, samt vattentätning och korrosionsbeständighet.

Åtta fördelar

1. Slät och ren

Plywooden skarvas tätt och smidigt.Efter avformningen överstiger betongkonstruktionens yta och jämnhet de tekniska kraven för den befintliga klarvattenformningen.Ingen sekundär putsning krävs, vilket sparar arbete och material.

2. Lätt och lätt att installera

Låg vikt, stark processanpassningsförmåga, kan sågas, hyvlas, borras, spikas och kan formas till vilken geometrisk form som helst för att möta behoven hos olika former av byggnadsstöd.

3. Enkel avformning

Betongen fastnar inte på träplywoodytan, kräver inget släppmedel, är lätt att ta ur formen och är lätt att rengöra dammet.

4. Stabil och väderbeständig

Hög mekanisk hållfasthet, ingen krympning, ingen svullnad, ingen sprickbildning, ingen deformation, ingen deformation, storleksstabilitet, alkali- och korrosionsbeständighet, flamskyddande och vattentät, resistent mot gnagare och insekter under temperaturförhållandena -20 ℃ till 60 ℃.

5. Befrämjar underhåll

Mallen absorberar inte vatten och kräver inget särskilt underhåll eller förvaring.

6. Stark variation

Typer, former och specifikationer kan anpassas efter byggprojektens krav.

7. Minska kostnaderna

Det finns många återanvändningstider, den plastbelagda plywooden är inte mindre än 25 gånger, så användningskostnaden är låg.

8. Energibesparing och miljöskydd

Allt skrot och använda mallar kan återvinnas, utan avfallsutsläpp.

Parameter

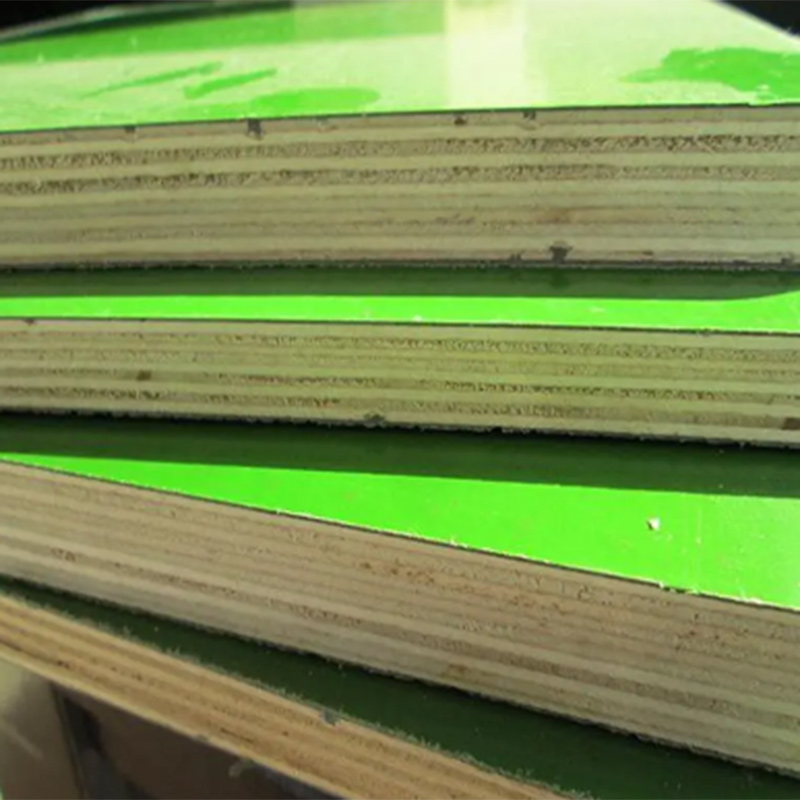

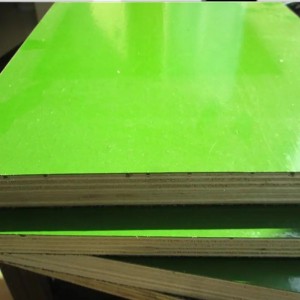

| Härstamning | Guangxi, Kina | huvudmaterial | tall, eukalyptus |

| Varumärke | Xinhang | Kärna | tall, eukalyptus eller efterfrågas av kunder |

| Modellnummer | Plastbelagd plywood | Ansikte/baksida | Grön plast/anpassad (kan skriva ut logotyp) |

| Betyg/certifikat | Lim | MR, melamin, WBP, fenol, etc. | |

| Storlek | 1830mm*915mm | Fukthalt | 5%-14% |

| Tjocklek | 11,5 mm ~ 18 mm eller efter behov | Densitet | 620-680 kg/cbm |

| Antal lager | 8-11 lager | Förpackning | Standard exportförpackning |

| Leveranstid | Inom 15 dagar efter beställning bekräftad | MOQ | 1*20GP.Mindre är acceptabelt |

| Användande | Utomhus, broar, höghus, tunnlar och andra projekt m.m. | Betalningsvillkor | T/T, L/C |